Onduline easyline roofing sheets have a 10 year waterproofing guarantee providing they have been installed inline with onduline recommended installation guidelines and the correct onduline accessories ridge verge fixings have been used.

Onduline roof sheet fixings.

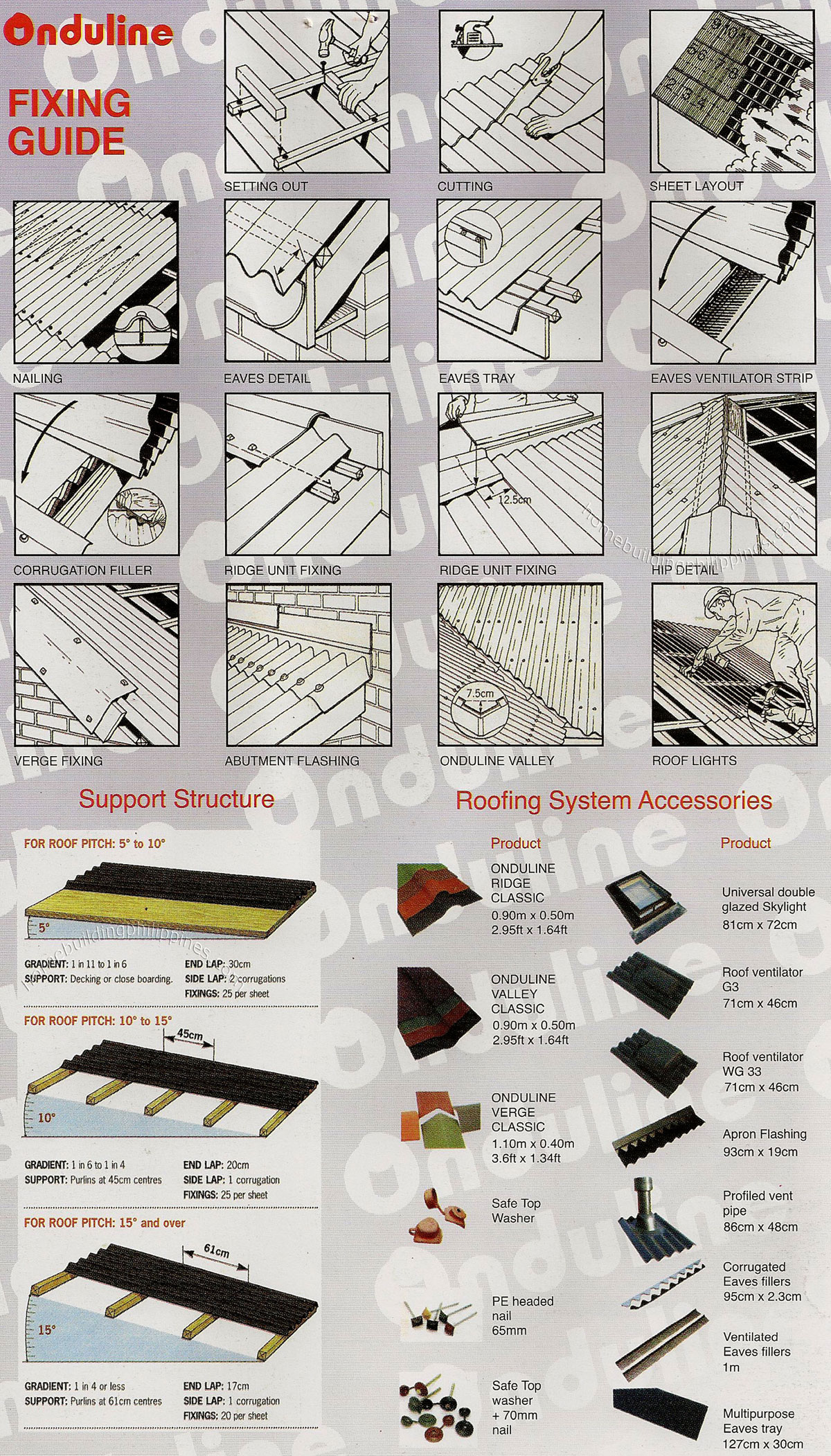

Up signs indicate the direction of the ridge to lay the sheets correctly.

Fixed with an onduline seal smart head with uv stabilization.

Fixing 5 screws at each corrugation at the end overlap or eaves.

The first raw of fixings at eave is located at 2 5 cm from the edge of the roof support osb or purlin.

Onduline building products ltd onduline offers reliable and durable roofing and waterproofing solutions to a wide range of buildings such as individual houses institutional commercial and industrial buildings.

Lay sheets in the opposite direction to the prevailing winds.

3 screws at first intermediate purlin of the sheet.

Start laying sheets over the gutter with 6 cm overhang maximum.

170mm coverage per sheet.

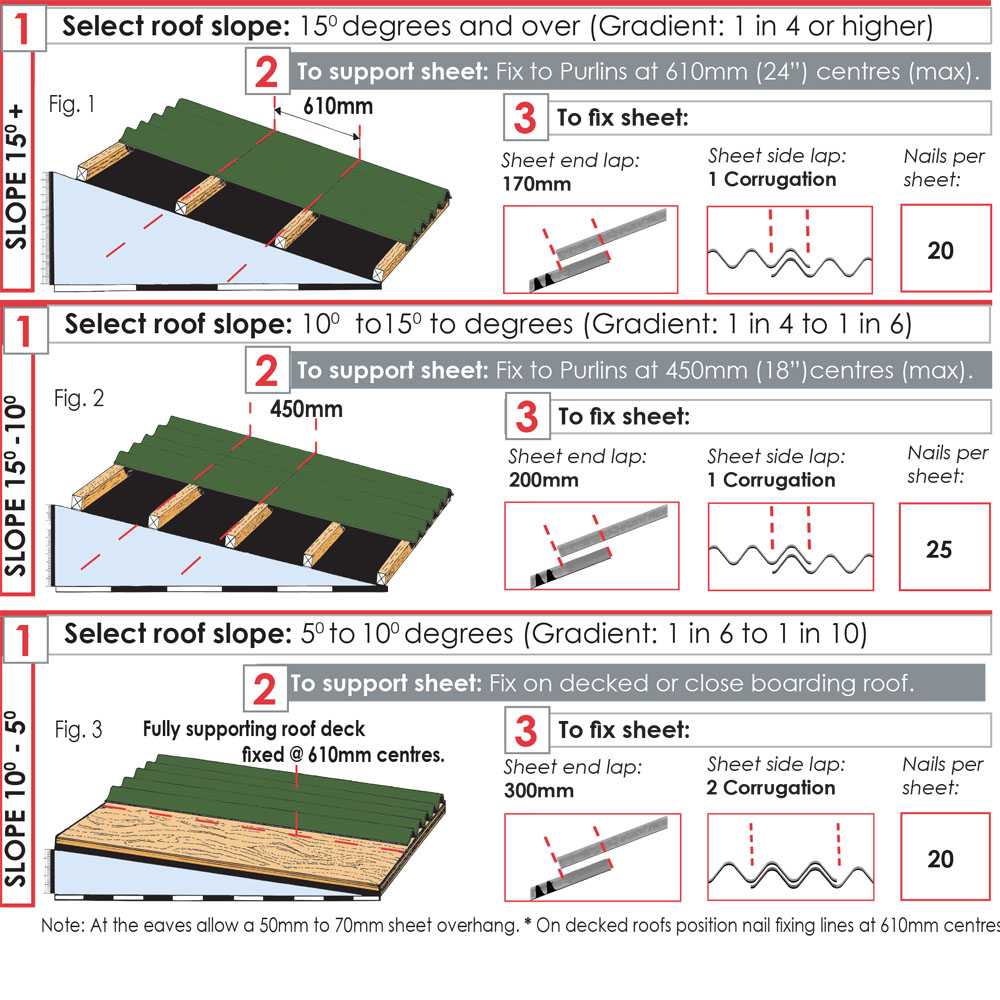

1 in 4 or less 2 end lap.

Screws should be drilled at each corrugation at the end start.

20 per sheet roof pitch.

3 screws at third intermediate purlin of the sheet.

Onduline roof support design roof pitch 15o and over 610mm gradient.

1 corrugation span of 610mm.

10o to 15o 450mm.

The fixings are a polished galvanised steel in 65mm.

Recommended minimum fixings per sheet 20.

Onduline is a world leader in manufacturing bituminous corrugated roofing materials.