This website stores cookies on your computer.

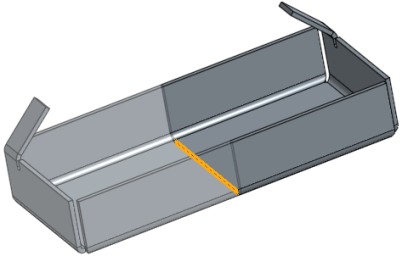

Onshape sheet metal hem.

Tab add a tab to a sheet metal flange.

If you re at the pacific design and manufacturing 2017 conference today in anaheim california please stop by the onshape agile design pavilion booth 3401 to see the first live demo of our soon to be released simultaneous sheet metal tools.

You can still get a sneak preview of onshape sheet metal by watching this video.

To create one or more hems on existing sheet metal parts first have a sheet metal part in the part studio.

In this webinar we took a look at the sheet metal tools available and how to get the most out of them.

There are three hem types to choose from.

Then select an edge or side face of a sheet metal part and define the details of your hem.

The power of a modern cad platform.

Sheet metal is lightweight inexpensive and easily formed into almost any shape.

Make joint convert the intersection of two walls into a joint feature either a bend walls joined by cylindrical geometry or a rip small gap between two walls.

Corner modify a corner type and relief scale.

Onshape saves you time with parametric modeling 2 0 a fundamentally better way to model using multi part design configurations simultaneous sheet metal tools standard content and managed in context design.

This can make a nice smooth finish and it also improves the strength of the edge of the sheet metal.

I tried breaking it into many sides by sketching two equal sided polygons and lofting between them and then step bending that but that does not work either.

Onshape s approach to designing sheet metal parts has many advantages.

Choose a direction using the flip arrow.

If you re unable to say hello in person there s good news.

Create one or more hems on existing sheet metal parts.

To get started click the hem feature from the list of sheet metal tools in the toolbar.

These cookies are used to collect information about how you interact with our website and allow us to remember you.

While in a part studio click.

I know onshape said they do not support rolled sheet metal at this point.

Instructor a hem is basically another name for bending over the edge of the sheet metal.

Select the edges or side faces along which to create hems.